Welding protective workwear serves as essential personal protective equipment (PPE) for welders, designed to resist ignition from sparks, prevent fabric melting, and reduce thermal exposure. Xinxiang Chuangwei Garment Co., Ltd. has developed practical solutions for welding environments through years of production experience.

The company’s welding garments are made exclusively from FR-treated cotton or cotton-blend fabrics—avoiding standard polyester or other thermoplastic fibers that can melt and adhere to skin during high-temperature exposure. Depending on customer requirements, the garments can meet Class 1 or Class 2 protection levels under EN ISO 11611, covering different intensities of welding activity.

Design features include extended hems, high necklines, and elasticated or buttoned cuffs to minimize spark entry. These details are based on feedback from industrial users and align with common industry practices.

In export markets, Chuangwei Garment observes that European buyers typically request full EN ISO 11611 test reports, while customers in the Middle East or Southeast Asia may prioritize core FR performance and cost efficiency. To accommodate diverse needs, the company offers flexible fabric and construction options based on target standards and budget considerations.

For proper use and maintenance, the following recommendations are provided:

Do not wash with chlorine bleach or fabric softeners;

Avoid applying oily substances to the garment surface;

Inspect regularly for holes, excessive wear, or heavy oil/grease buildup;

Replace garments if the fabric becomes stiff, discolored, or shows reduced FR performance.

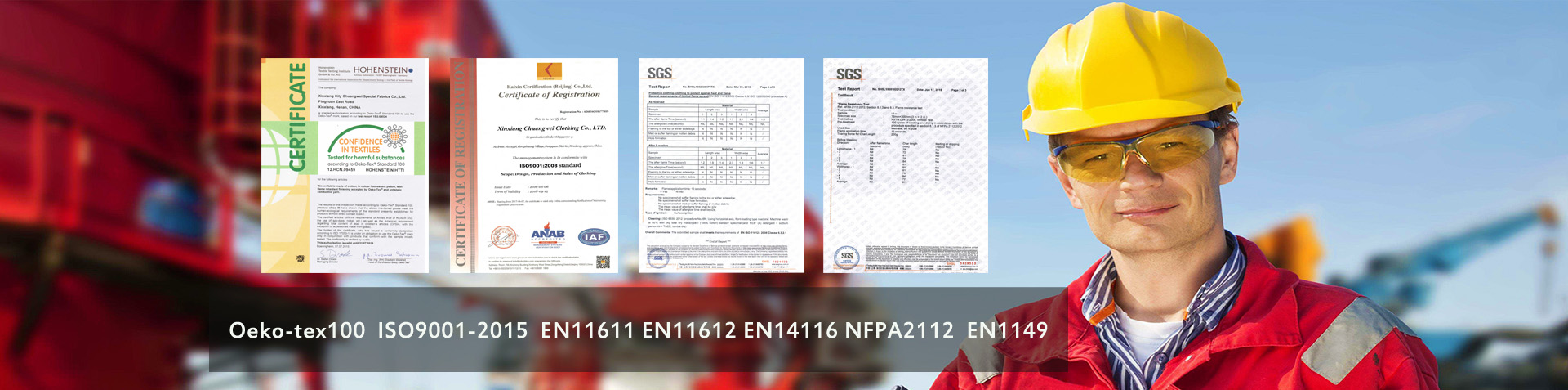

Chuangwei Garment does not claim “permanent protection” or “absolute safety.” Instead, it supplies garments that meet recognized testing standards and provides factual guidance to support safe usage. Customers seeking welding protective solutions are welcome to contact us for technical documentation or sample requests.