In high-risk environments such as steel mills, chemical plants, and electrical emergency repairs—where exposure to high temperatures and open flames is common—protective clothing plays a critical role in ensuring worker safety. Among the available options, aramid flame-resistant (FR) protective garments stand out for their performance and reliability. Understanding their key features and appropriate applications is essential for effective protection.

Inherently Flame-Resistant: Beyond Chemical Treatments

Flame-resistant workwear on the market generally falls into two categories:

Chemically treated FR fabrics: These rely on surface-applied flame-retardant chemicals to achieve fire resistance. However, their protective performance often degrades after repeated laundering.

Inherently flame-resistant fabrics, such as those made from aramid fibers (e.g., Nomex®): Their flame resistance stems from the molecular structure of the fiber itself—no external coatings or additives are needed.

Aramid fibers maintain their fundamental physical properties even at temperatures around 200°C. When exposed to direct flame, they do not ignite or melt/drip; instead, they char and form a protective carbonized layer that insulates against heat. Rigorous testing confirms that certified aramid FR garments retain their flame-resistant properties even after multiple washes, consistently meeting relevant safety standards.

Balancing Safety and Comfort

Traditional FR clothing can sometimes be heavy and poorly breathable, leading to heat stress during prolonged wear. In contrast, aramid-based FR garments offer a better balance—they are relatively lightweight and provide inherent breathability and heat dissipation.

Modern designs further enhance wearer comfort through thoughtful details:

Ergonomic 3D cutting reduces fabric-to-skin friction.

Elasticated cuffs and collars help prevent sparks or debris from entering.

Strategic use of breathable paneling in high-sweat zones improves airflow.

These features ensure reliable protection without compromising mobility or comfort during extended shifts.

Recommended Applications and Selection Tips

Aramid FR protective clothing is ideal for occupations involving open flames, high heat, or molten metal splashes—common in industries such as metallurgy, petrochemicals, power utility repair, and emergency response. It’s also suitable for certain welding and cutting operations where flame resistance is required.

When selecting FR garments, consider the following three factors:

Fiber composition: Choose products that clearly specify the use of inherently FR fibers like meta-aramid.

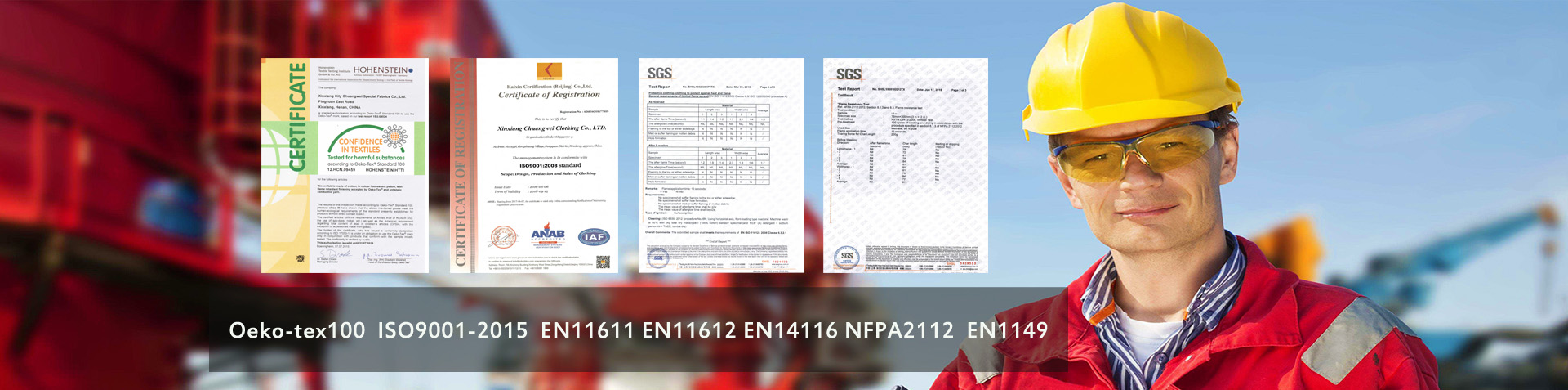

Certification & compliance: Verify that the garment comes with test reports from accredited laboratories and complies with standards such as GB 8965.1-2020 “Protective Clothing – Flame-Resistant Garments.”

Design & fit: Select styles (e.g., coveralls vs. two-piece sets) based on job requirements, and ensure proper sizing—garments that are too loose or too tight can compromise both safety and functionality.

Foundational Safety Awareness

For workers in high-temperature environments, protective clothing is a vital component of overall safety. Aramid flame-resistant garments deliver proven, standards-compliant protection—but their effectiveness depends on correct usage, proper maintenance, and adherence to workplace safety protocols.

By combining advanced materials, intelligent design, and rigorous standards compliance, Chuangwei Garments’ aramid FR protective clothing empowers professionals to work safely and confidently in the most demanding conditions.